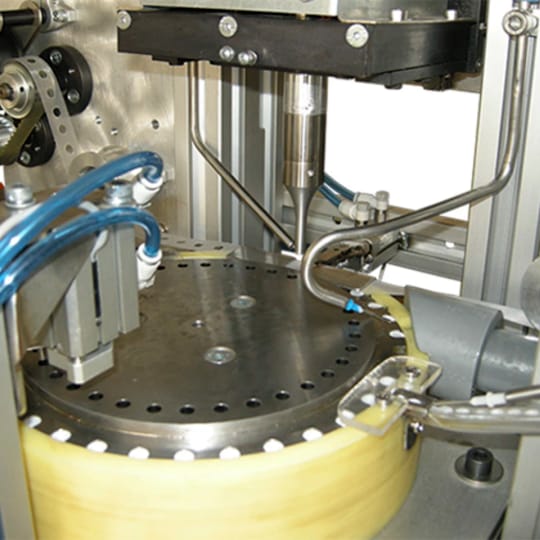

The machine is designed for production of the foaming element, which is mounted to the pumps for cosmetic products, such as liquid soaps, shaving foams, hair dyes and others that need to be aerated (repleted with air).

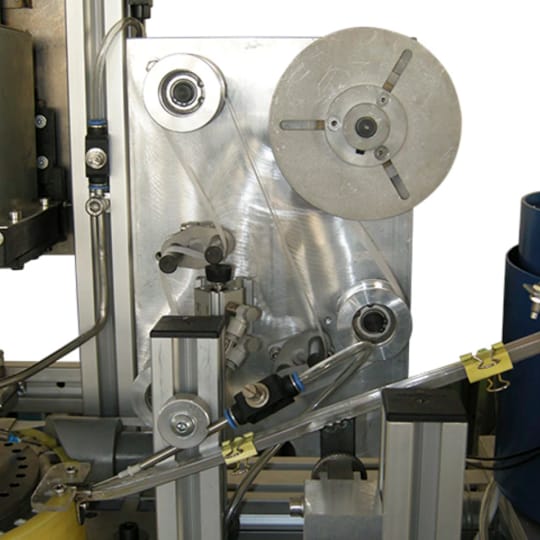

The whole equipment consists of five modules, operating synchronously, which punch polypropylene mesh and weld the punched element on a ring, for production of the finished detail.

The machine features high efficiency of 1 detail per second. The process of ultrasonic punching and welding takes 0,2 to 0,3 sec. The processed materials have to be identical and applicable for ultrasonic welding. The quality of welding depends on the quality of materials.