Anode oxidation of aluminum adds hardness and decorative coloring. Hard anode oxidation increases surface hardness and wear resistance several times.

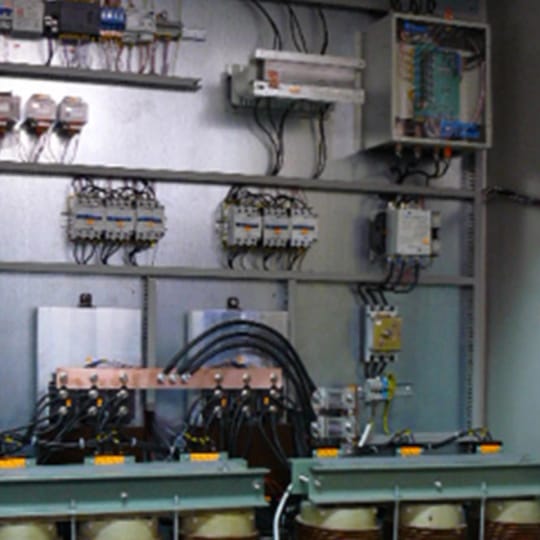

The equipment consists of different containers placed consecutively to ensure conformity to technological requirements. Rectifier is designed for anodizing technology. Process-controller is built on Simatic PLC with remote control panel.

The equipment comprises of rectifiers for anode oxidation as well as rectifiers for hard anode oxidation and electroplating.

The rectifiers are current controllable by several control modes – direct current, pulsating (pulsatory) current, increasing and decreasing current. There are several rectifier protections – short circuit protection, output protection, disconnected load of the container, etc.

Depending on the technological requirements, we produce rectifiers of different types and for different purposes

Equipment for anode oxidation and hard anode oxidation of aluminum

Equipment for anode oxidation and hard anode oxidation of aluminum

€0.00 / BGN 0.00

€0.00 / BGN 0.00